FINAL PRODUCT'S description

YOFC/ZTT Machines’ Supplier, the first one in China to make this machine with a speed of 400m/min!

What’s the Steel Wire Coated cable?

Coating the surface of the FTTH drop cable is used to increase its torsional resistance and friction, so it will not be affected by twisting during construction.

Structurally the Steel Wire Coated consists of the following components.

Messenger Wire

Jacket

How to produce the Steel Wire Coated cable?

So just need one line to do this cable:

HK-30 IPC+PLC Control Steel Wire Coated Production Line can finish all the processes, for Jacket material normal using EAA/EVA

- Overview

- Related Products

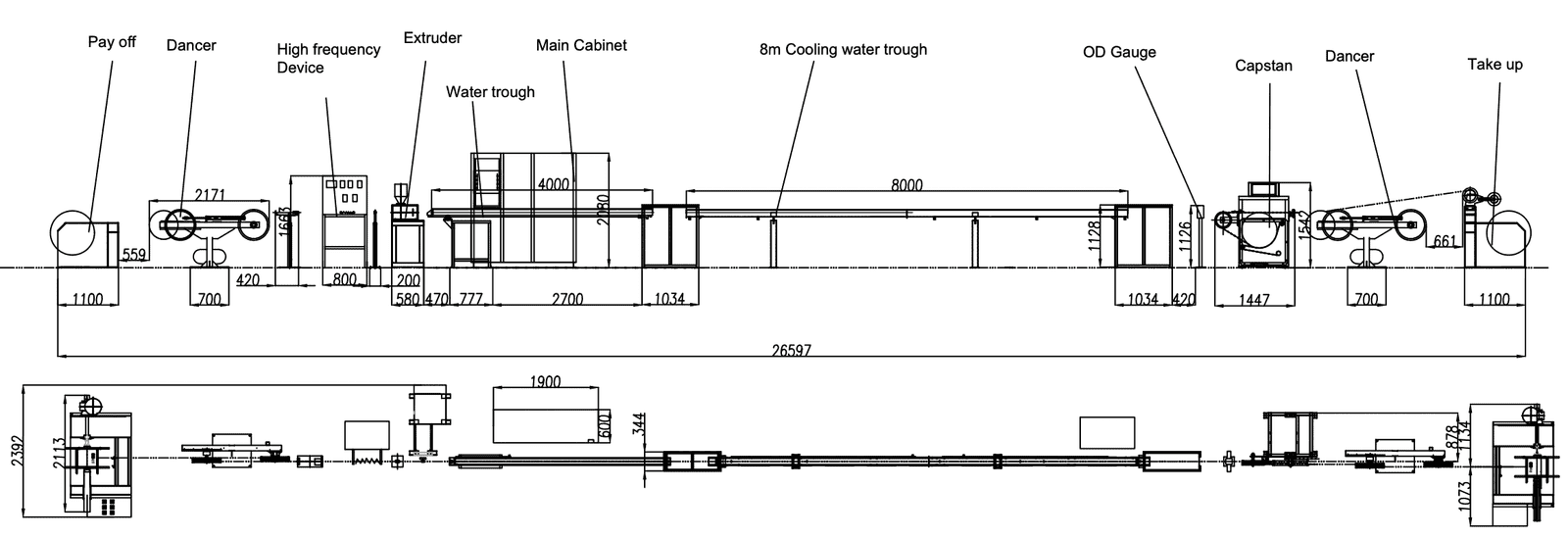

- Single head shaft-less automatic pay-off: place the 800mm steel wire(park rising/galvanization).

- Pneumatic control tension dance device: PID closed-loop control with displacement sensors.

- Induction heating machine: heating the steel wire before the extruder.

- Main extruder: Motor: Siemens, Transducer: Emerson, extrusion the EAA, EVA material, Line speed can reach 400m/min

- Main cabinet: IPC+PLC control; IPC: Taiwan Advantech, PLC: Siemens.

- Cooling water trough+ tank: 4m+8m water tough allows the material to cool and harden gradually to control the outside diameter.

- Diameter gauge: display the actual diameter on the screen.

- Capstan: Motor: Panasonic servo + Emerson transducer control.

- Pneumatic control tension dance device: PID closed-loop control with displacement sensors.

- Single head shaft-less automatic take-up: Electric hydraulic lift, pneumatic clamping; Motor: Siemens, Transducer: Emerson; Traverse part: Japan Panasonic Servo Motor with Ball Screw and Linear Guide Control.

HK-30 IPC+PLC CONTROL STEEL WIRE COATED PRODUCTION LINE

HK-30 IPC+PLC Control Steel Wire Coated Production Line

HK 30 steel wire coated machine’s layout