- Overview

- Related Products

-

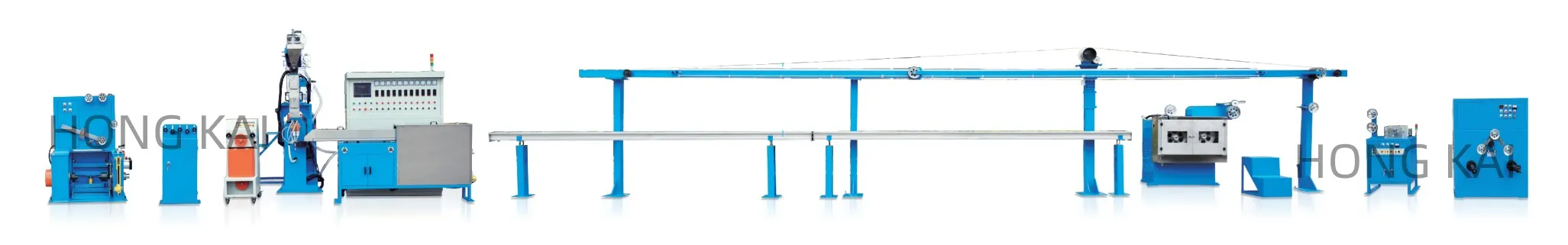

High-Precision Extrusion: Ensures consistent and accurate production for PE PP PVC Single Wall Corrugated Pipe Plastic Flexible Tube Pipe Hose Production Line Extruder Making Machines.

-

Versatile Functionality: Capable of producing LAN cables, UTP/STP/FTP cables, and PU wire hoses for Cat5/Cat6 networks.

-

High-Speed Production: Optimized for efficient and continuous operation, reducing production time.

-

Robust Construction: Built to withstand demanding industrial environments, ensuring long-lasting performance.

-

Automated Control System: Provides seamless automation for enhanced accuracy and reduced manual intervention.

-

Energy Efficiency: Designed to minimize energy consumption while maximizing output.

-

User-Friendly Interface: Simplifies operation and maintenance, ensuring minimal downtime.

-

Telecommunication Networks: Producing high-quality LAN cables for reliable communication infrastructure.

-

Fiber Optic Manufacturing: Ideal for Double Wall Corrugated Pipe Machine Lines requiring precision and consistency.

-

Industrial Cable Systems: Perfect for Conduit Pipe Extrusion Lines, providing superior performance and flexibility.

-

Outdoor Cable Systems: Supports the creation of robust cables and pipes for harsh outdoor environments.

Key Features:

Applications:

The PVC Extrusion Equipment - LAN Cable Extrusion Line is widely used in the production of various cables and pipes, making it an essential tool for:

With its advanced technology and versatile functionality, the PVC Extrusion Equipment - LAN Cable Extrusion Line from Hongkai is the ultimate choice for businesses seeking to enhance their Outdoor Optical Cable Equipment production capabilities.

|

No

|

Item

|

Data

|

|

1

|

No. Of pay off:

|

1

|

|

2

|

Tension of pay off:

|

1~5N±0.3N

|

|

3

|

Wire coaxiality:

|

95%

|

|

4

|

Extrusion output:

|

110KG/H

|

|

5

|

Copper wire pay-off reels:

|

PN400 -500mm reels

|

|

6

|

Copper wire Specification:

|

ø0.3---1.5mm

|

|

7

|

Pay-off tension of Copper wire:

|

5N-20N

|

|

8

|

Extruder size:

|

Φ50x26D

|

|

9

|

Final product:

|

CAT5/CAT6/CAT7

|

|

10

|

Structure speed:

|

Max 500m/min

|

|

11

|

Production speed:

|

450m/min(0.95mm)

|

|

12

|

Center height of machine:

|

1000mm height from ground

|

|

13

|

Power:

|

Approximate 35KW

|

|

14

|

Weight:

|

5 ton

|

|

15

|

Line length:

|

28M

|

|

16

|

Machine power:

|

380V 50HZ three phase five wire

|

|

17

|

Line direction:

|

It’s up to customer

|

|

18

|

Range of air pressure:

|

0.3---0.6MPa

|

|

19

|

Machine color:

|

It’s up to customer

|

|

20

|

Take-up tension:

|

5-20N

|

|

21

|

Take-up reels Specification:

|

400 reel and 630 reel(central shaft hole diameter ø 56)

|

|

1.

|

Φ400—Φ500mm single head shaftless motorized pay off rack (No.: ZDFX-00)

|

|

2.

|

Automatic induction copper wire preheater (No.:ZZT-00)

|

|

3.

|

Copper wire straight platform(with tool box) (No.:YRQ-00)

|

|

4.

|

Φ50+35 extrusion main motor(U7 free-adjustment machine head)

(No.:50JSJ-00) |

|

5.

|

50KG Dryer machine and automatic hopper

|

|

6.

|

Electric apparatus, main temperature control cabinet(PLC control)(No.:50GKDX-00)

|

|

7.

|

1.5m primary and secondary moving warm water trough(with blowing device)(No.:1.5MYDRSC-00)

|

|

8.

|

Shanghai GONGJIU single type laser diameter gauge

|

|

9.

|

8m single-layer U type fixed cooling water trough (No.:8MGDSC-00)

|

|

10.

|

Φ400mm double wheel capstan

|

|

11.

|

9m horizontal tension wire accumulator(with slide plate)(No.:9MCXJ-00)

|

|

12.

|

15KV high frequency spark machine

|

|

13.

|

Φ400~630mm double-shaft take-up machine(No.:630SZSX-00)

|