IPC+PLC Control Fiber Optic Cable Production Line for ADSS

The IPC+PLC Control Fiber Optic Cable Production Line for ADSS by Hongkai is a cutting-edge solution designed for the Outdoor Optical Cable Equipment industry. This advanced production line integrates IPC+PLC control technology, ensuring precision, efficiency, and reliability in the manufacturing of ADSS cables. Ideal for fiber optic cable production lines, Outdoor cable production lines, and ADSS cable production lines, this equipment is engineered to meet the highest industry standards, delivering exceptional performance for outdoor optical cable production.

- Overview

- Related Products

-

IPC+PLC Control System: Provides seamless automation and real-time monitoring for enhanced production accuracy.

-

High-Speed Production: Optimized for efficient and continuous operation in fiber optic cable production lines.

-

Precision Engineering: Ensures consistent quality and performance for ADSS cable production lines.

-

Robust Construction: Built to withstand demanding industrial environments, ensuring long-lasting performance.

-

Versatile Functionality: Capable of handling various cable types, including ADSS and other outdoor optical cables.

-

Energy Efficiency: Designed to minimize energy consumption while maximizing output.

-

User-Friendly Interface: Simplifies operation and maintenance, reducing downtime.

-

Telecommunication Networks: Producing high-quality ADSS cables for reliable communication infrastructure.

-

Fiber Optic Manufacturing: Ideal for fiber optic cable production lines requiring precision and consistency.

-

ADSS Cable Systems: Perfect for ADSS cable production lines, providing superior performance and flexibility.

-

Outdoor Cable Systems: Supports the creation of robust cables for harsh outdoor environments.

Key Features:

Applications:

The IPC+PLC Control Fiber Optic Cable Production Line for ADSS is widely used in the production of outdoor optical cables, making it an essential tool for:

With its advanced technology and versatile functionality, the IPC+PLC Control Fiber Optic Cable Production Line for ADSS from Hongkai is the ultimate choice for businesses seeking to enhance their Outdoor Optical Cable Equipment production capabilities.

Product Application

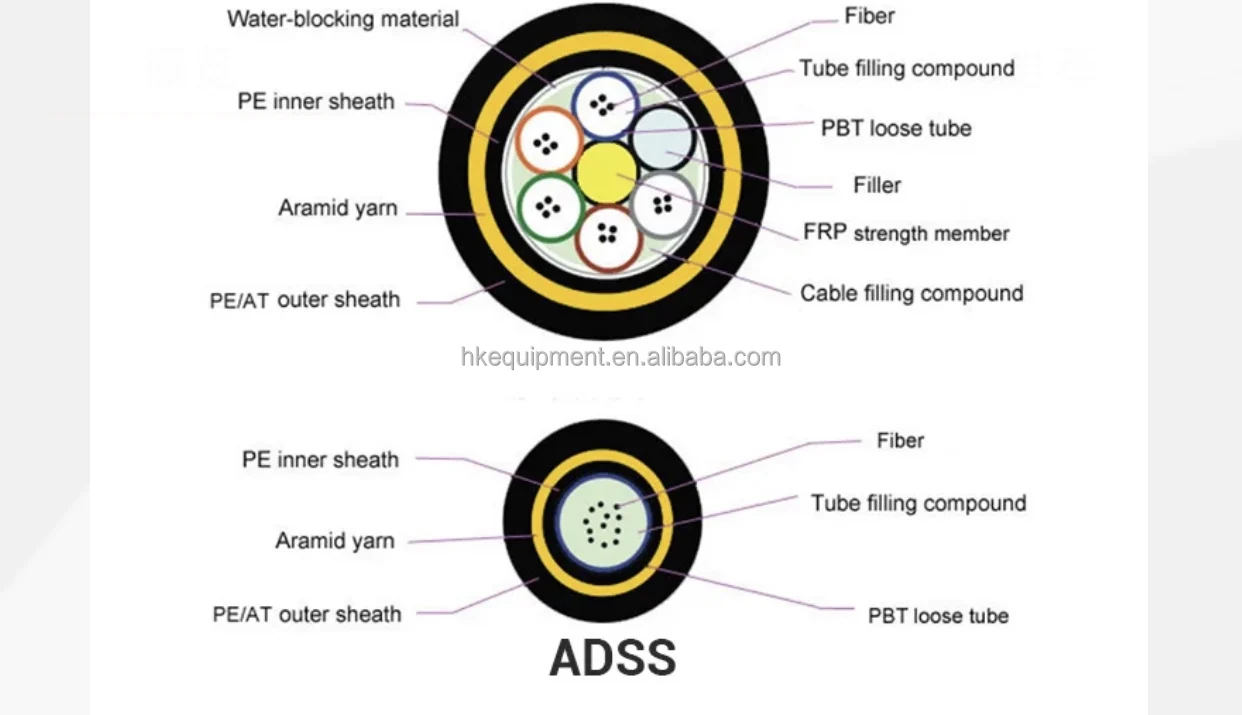

1.PE inner sheath,aluminum-plastic compound belt and PEineer sheath;

2.PE outer sheath,aluminum-plastic compound belt,PE composite outer sheath,steel-plastic compound belt,PE composite outer sheath;

3.Parallel double steel wire tube bundling type optic-fiber cable;

4.ADSS optic cable,etc.

5.the cable machinery is suitable for optical cable outer sheath and core stengthening comprehensive production, also can be used for inner protection layer production.

Main accessories brand:

1)Motor:Siemens motor3)Temperature controller: Japan RKC Brand PID Smart type

4)Industrial Controller: Taiwan ADVANTECH

5)PLC: Siemens S7 series

6)Screw & Barrel: Produced byJINHUCompany from Zhejiang Province,China.

7)Low voltage electrical parts: Adopts Janpan OMRON,YANGMING, SCHNEIDER brands, etc.

1.Φ800~1600mm Portable Cantilever type motorized pay-off rack

2. Swing Type Pay-off Tension Dance Wheel Device

3. Φ630mm-800mm Steel Wire Pay-Off and Guiding Device(including steel wire straightening device)

4. Φ1000mmDual Pad Metal (Steel-Aluminium Tape) Pay-Off

5.Metal Tape (Steel-Aluminium Tape) Accumulator

6.On-Line Seam Welding Device (Steel & Aluminium Tape)

7.Metal Tape (Steel-Aluminium Tape) Corrugating Device

8.Metal Tape (Steel-Aluminum) longitudinal forming device

9.Φ90mm extrusion main motor

10.Adjustable machine-head and clip

11.75kg dryer and automatic hopper

12.Electric apparatus, temperature main control cabinet

13.4m movable warm water trough and warm water tank

14.25m single-layer U-type stainless steel cooling water trough

15.Drying device

16.laser diameter gauge

17.Color-tape meter-counting printer machine

18.1200kg Caterpillar type Capstan machine

19.Swing type take-up tension dance wheel device

20.Φ800~1600mm single shaft cantilever take-up and traverse machine