30 Tight-Buffered Fiber Production Line-Optical Fiber Cable Extruder Machine

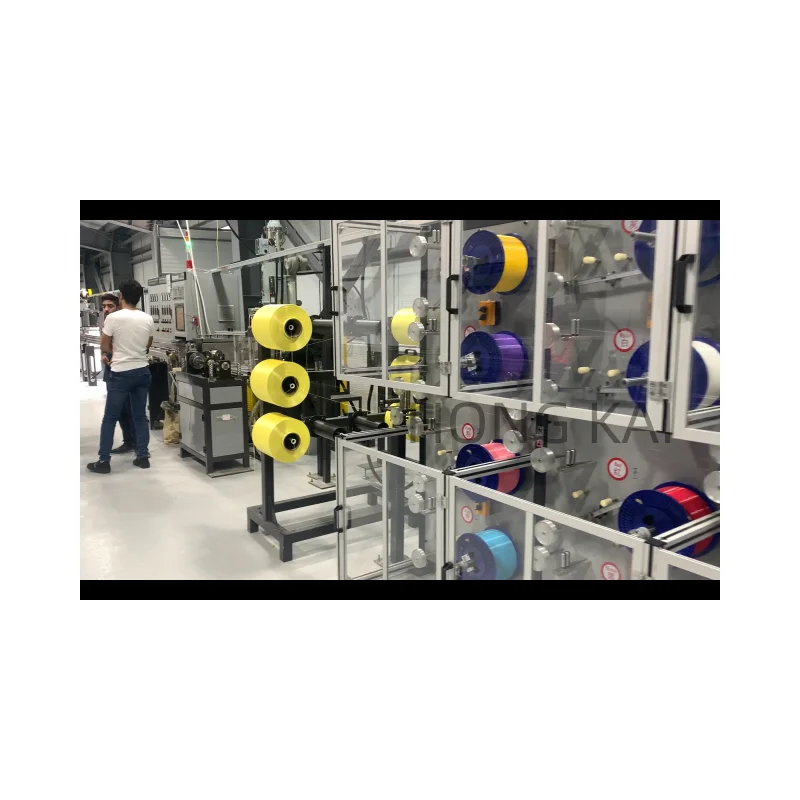

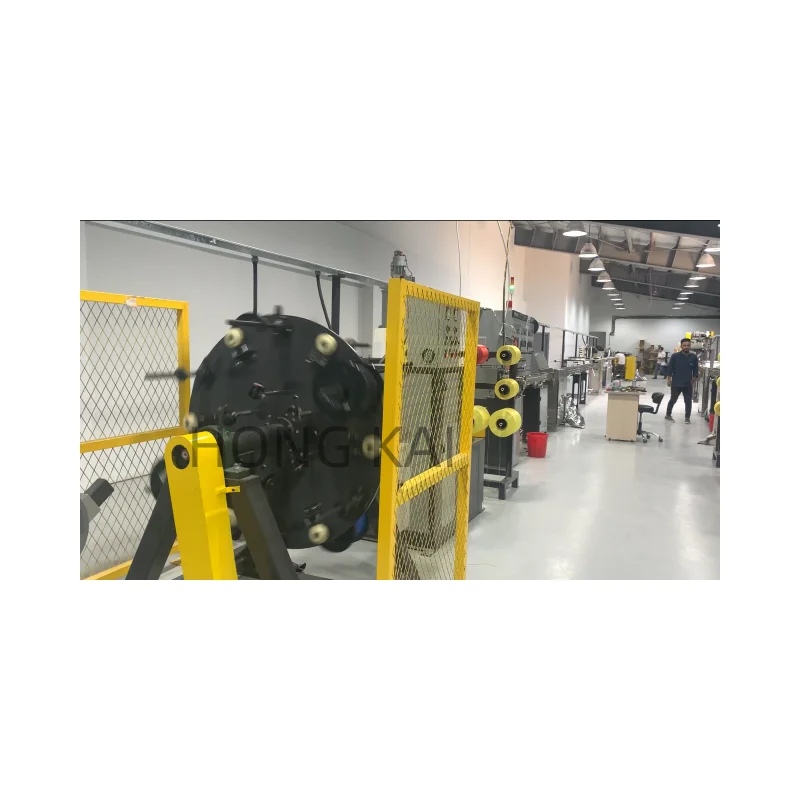

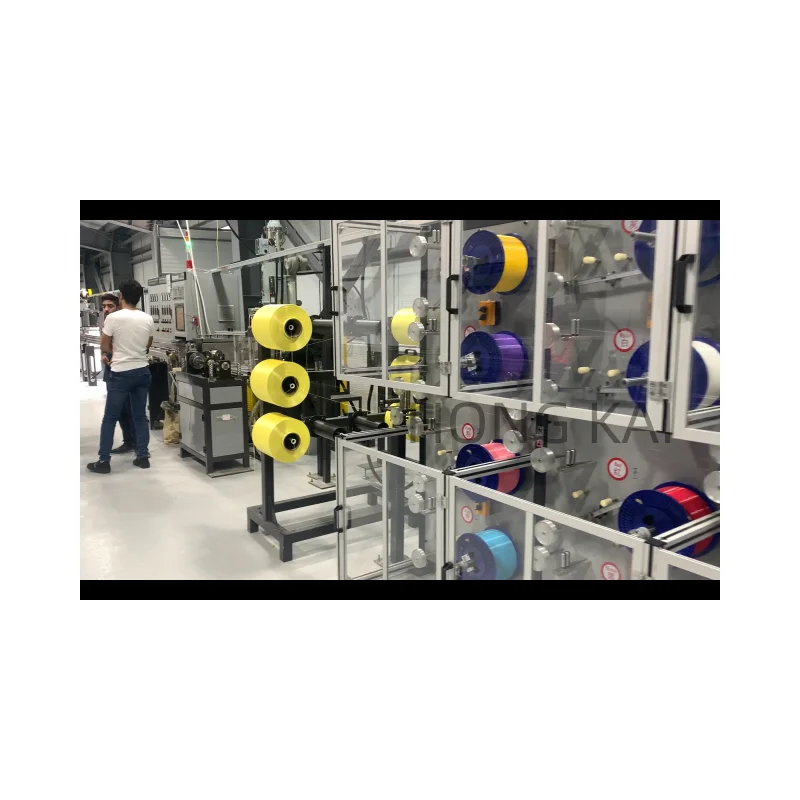

The 30 Tight-Buffered Fiber Production Line - Optical Fiber Cable Extruder Machine by Hongkai is a state-of-the-art solution designed for the Indoor Optical Cable Equipment industry. This advanced production line integrates Optical Fiber Cable Extruder Machine technology, ensuring precision, efficiency, and reliability in the manufacturing of 30 Tight Buffered fibers. Ideal for fiber optic cable manufacturing machines, this equipment delivers exceptional performance for indoor optical cable production.

- Overview

- Related Products

-

High-Precision Extrusion: Ensures consistent and accurate production for Optical Fiber Cable Extruder Machines.

-

Automated Control System: Features advanced automation for seamless operation and reduced manual intervention.

-

High-Speed Production: Optimized for efficient and continuous operation, reducing production time.

-

Compact Design: Space-saving and ideal for indoor manufacturing environments.

-

Energy Efficiency: Designed to minimize energy consumption while maintaining high productivity.

-

User-Friendly Interface: Simplifies operation and maintenance, ensuring minimal downtime.

-

Versatile Compatibility: Suitable for various fiber optic cable manufacturing machine applications.

-

Telecommunication Networks: Producing high-quality 30 Tight Buffered fibers for reliable indoor connectivity.

-

Fiber Optic Manufacturing: Ideal for fiber optic cable manufacturing machines requiring precision and consistency.

-

Data Centers: Ensuring efficient and reliable cable production for indoor networking needs.

-

Residential and Commercial Use: Supports the production of durable and high-performance tight-buffered fibers for indoor applications.

Key Features:

Applications:

The 30 Tight-Buffered Fiber Production Line is widely used in the production of indoor optical cables, making it an essential tool for:

With its advanced technology and versatile functionality, the 30 Tight-Buffered Fiber Production Line from Hongkai is the ultimate choice for businesses seeking to enhance their Indoor Optical Cable Equipment production capabilities.

|

1.

|

No. Of optical fiber pay off:

|

2

|

|

2.

|

Tension of pay off:

|

0.3~1.5N±0.05N

|

|

3.

|

Reel of optical fiber pay off:

|

25km and 50km standard fiber reel

|

|

4.

|

Extruding material:

|

PVC, LSZH, Hytrel

|

|

5.

|

Plasticization degree:

|

100%

|

|

6.

|

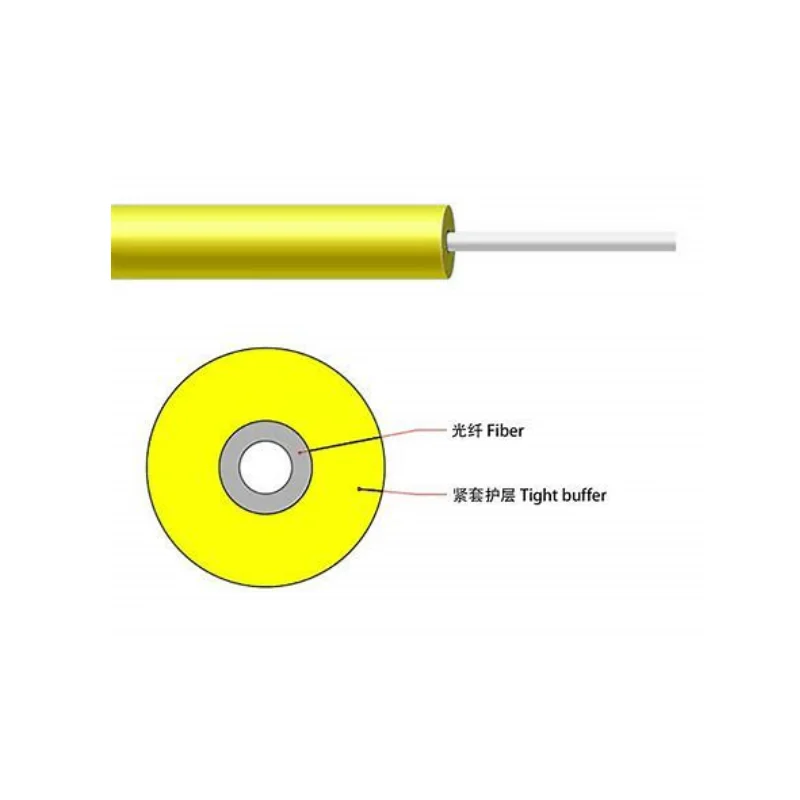

Fiber diameter:

|

ø0.25mm

|

|

7.

|

Extrusion output:

|

30KG/hr( cross head is open)

|

|

8.

|

Extruder size:

|

Φ30x25D

|

|

9.

|

Final product:

|

0.6mm/0.9mm tight buffer fiber

|

|

10.

|

Structure speed:

|

Max 350m/min

|

|

11.

|

Production speed:

|

100-300m/min

|

|

12.

|

Center height of machine:

|

1000mm height from ground

|

|

13.

|

Precision of meter-counter:

|

≤0.2%

|

|

14.

|

Additional loose after extrusion:

|

≤0.02dB/km(average value: 0.01 dB/km)

|

|

15.

|

Power:

|

Approximate 32KW

|

|

16.

|

Weight:

|

3.5 ton

|

|

17.

|

Line length:

|

21M

|

|

18.

|

Machine power:

|

380V 50HZ three phase five wire

|

|

19.

|

Line direction:

|

It’s up to customer

|

|

20.

|

Range of air pressure:

|

0.5-0.6MPa

|

|

21.

|

Machine color:

|

Dark blue

|

|

22.

|

Temperature of pre-heater:

|

50~300℃

|

|

23.

|

Take-up tension:

|

0.5-3N

|

|

24.

|

Take-up reels Specification:

|

Φ236mm fiber standard reel and Φ400 reel

|

|

1.

|

Double heads motorized pay-off rack(No.: 2GQZDFX-00)

|

1set

|

|

2.

|

Preheating oven (No.:GQYRZZ-00)

|

1set

|

|

3.

|

Φ30mm Extrusion main motor (No.:30JSJ-00)

|

1set

|

|

4.

|

25KG Dryer machine and automatic hopper

|

1set

|

|

5.

|

Electric apparatus, temperature control (PLC+IPC control)

(No.:30GKDX-00)

|

1set

|

|

6.

|

2.5m moving water trough with water tank and warm water tank

(No.:2.5MYDRSC-00)

|

1set

|

|

7.

|

Shanghai Gongjiu laser diameter gauge

|

1set

|

|

8.

|

8 m U shape single-layer fixed water trough and cooling water tank

(No.:8MLQSC-00)

|

1set

|

|

9.

|

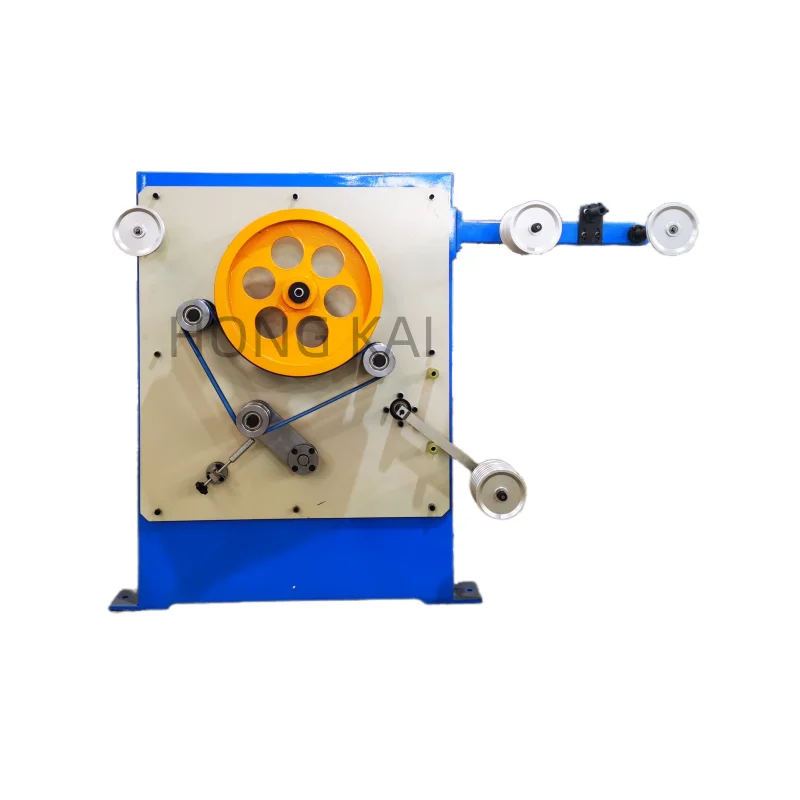

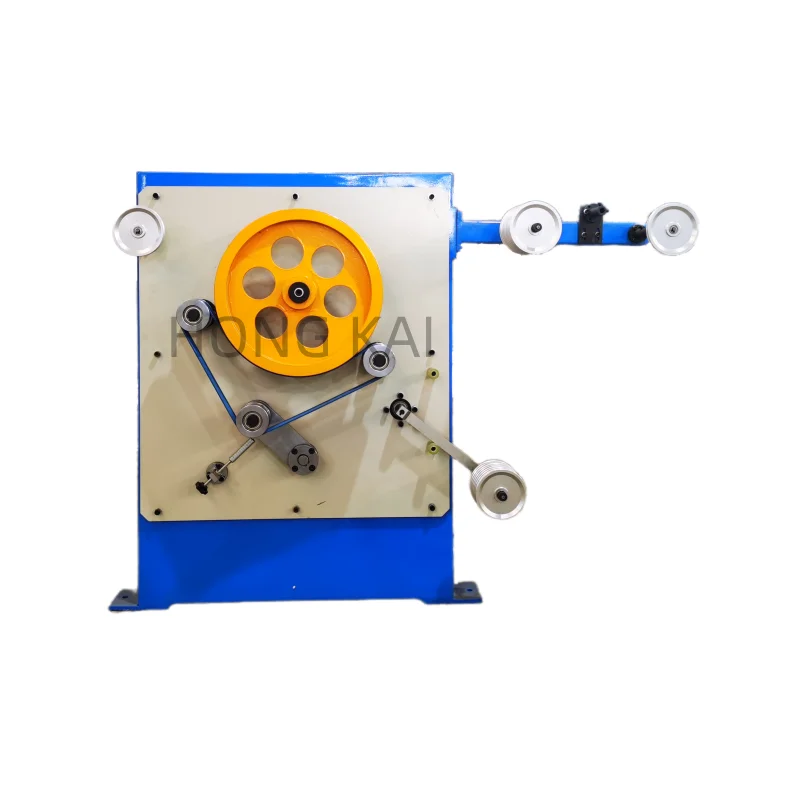

Φ400mm single-wheel capstan machine(including dance device)

(No.:400LSQY-00)

|

1set

|

|

10.

|

Φ236-400mm double-shaft take-up machine(No.:400DZSX-00)

|

1set

|