50 FTTH Terminal Extruder Machinery /Optical Fiber Drop Cable Machinery-Optical Fiber Cable Machine

The 50 FTTH Terminal Extruder Machinery / Optical Fiber Drop Cable Machinery - Optical Fiber Cable Machine by Hongkai is a cutting-edge solution designed for the Indoor Optical Cable Equipment industry. This advanced machinery integrates Optical Fiber Cable Extruder Machine technology, ensuring precision, efficiency, and reliability in the production of FTTH (Fiber to the Home) drop cables. Ideal for FTTH Cable Machines and FTTH Cable CATV Extrusion Production Lines, this equipment delivers exceptional performance for indoor optical cable manufacturing.

- Overview

- Related Products

-

High-Precision Extrusion: Ensures consistent and accurate production for Optical Fiber Cable Extruder Machines.

-

Automated Control System: Features advanced automation for seamless operation and reduced manual intervention.

-

High-Speed Production: Optimized for efficient and continuous operation, reducing production time.

-

Compact Design: Space-saving and ideal for indoor manufacturing environments.

-

Energy Efficiency: Designed to minimize energy consumption while maintaining high productivity.

-

User-Friendly Interface: Simplifies operation and maintenance, ensuring minimal downtime.

-

Versatile Compatibility: Suitable for various FTTH Cable CATV Extrusion Production Line applications.

-

Telecommunication Networks: Producing high-quality FTTH drop cables for reliable home and business connectivity.

-

Fiber Optic Manufacturing: Ideal for FTTH Cable Machines requiring precision and consistency.

-

CATV Systems: Perfect for FTTH Cable CATV Extrusion Production Lines, ensuring efficient cable production for broadcasting networks.

-

Residential and Commercial Use: Supports the production of durable and high-performance FTTH drop cables for indoor applications.

Key Features:

Applications:

The 50 FTTH Terminal Extruder Machinery / Optical Fiber Drop Cable Machinery is widely used in the production of indoor optical cables, making it an essential tool for:

With its advanced technology and versatile functionality, the 50 FTTH Terminal Extruder Machinery / Optical Fiber Drop Cable Machinery from Hongkai is the ultimate choice for businesses seeking to enhance their Indoor Optical Cable Equipment production capabilities.

1,machine application:

FTTH cable extruder machine mainly applied in the production of tight buffered fiber,soft optical fiber cable,FTTH terminal optical fiber cable(drop cable).The extruded sheath possesses the features of even diameter,smooth,fast speed, and low excess loss for optical fiber.

2,Technical parameters of optical fiber drop cable production line :

|

Extruder type |

50 ×25Extruder/ 65×25 Extruder |

|

extrusion material |

LSZH,PVC |

|

structure speed |

Max.150m/min |

|

production speed |

Max.100m/min(LSZH);120m/min(PVC) |

|

No of optical fiber pay-off reels |

2 reels |

|

Specification of optical fiber pay-off reels |

25km and 50km standard optical fiber reels |

|

Pay-off tension of optical fiber |

0.4N-1.5N |

|

Heads no of reinforcement pay-off rack |

2 heads |

|

Specification of reinforcement pay-off reels |

PN400 reels and ø254 ×ø116 ×ø180 ×ø32 reels |

|

reinforcement Specification |

ø0.4- ø1.0 |

|

Pay-off tension of reinforcement |

5N-20N |

|

Take-up tension |

5-2ON |

|

Take-up reels Specification |

PN400 reel and PN630 reel(central shaft hole diameter ø 56) |

|

excess loss after extrusion |

1550nm<=0.2dB/km(single mold optical fiber) |

|

Center height of machine |

1000mm from background |

|

Line length |

26m |

|

Power |

380V±10% 50Hz Three phase five line 58KW |

3,Main parts brand(can adjust according to customer's demand):

Motor: Siemens motor

Transducer: American Emerson transducer

IPC:Taiwan Yanhua

PLC:Siemens S7 series

Temperature controller:FOTEK temperature controller PID48 96 smart type

electrical parts: adopt OMRON,FOTEK,SHILIN brands, etc.

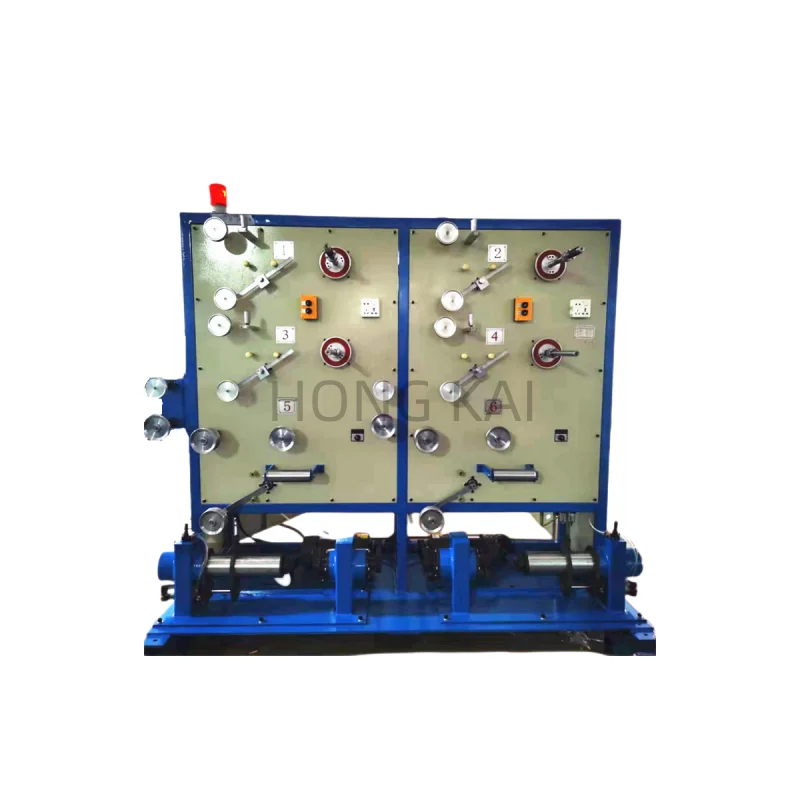

4,Main composition are as follows

|

NO |

All parts’ name and specification ofΦ50PLC |

Qty |

|

1 |

2 heads motorized pay-off rack |

1 set |

|

2 |

2 heads motorized reinforcement pay-off rack |

|

|

3 |

800 single head motorized pay-off rack with dancer |

1 set |

|

4 |

Copper wire straightening platform |

1 set |

|

5 |

Mobile positioning moldsupport |

1 set |

|

6 |

Φ50x25D Extrusion main motor |

1 set |

|

7 |

50KG Dryer machine |

1 set |

|

8 |

Automatic hopper |

1 set |

|

9 |

Electric apparatus, main temperature control cabinet(PC+PLC Computer process control) |

1 set |

|

10 |

2.5m moving water trough |

1 set |

|

11 |

8m single-layer U-type fixed type cooling water trough |

1 set |

|

12 |

water tank |

1 set |

|

13 |

Drying device |

1 set |

|

14 |

Shanghai gongjiu laser diameter gauge |

1 set |

|

15 |

Φ640+300 double-wheels capstan |

1 set |

|

16 |

9m horizontal tension wire accumulator with linear slide |

1 set |

|

17 |

PN400~630 double-shaft take-up machine |

1 set |

|

18 |

Stand-by parts |

1 set |

|

19 |

Providing tools |

1 set |

|

20 |

Providing data |

1 set |

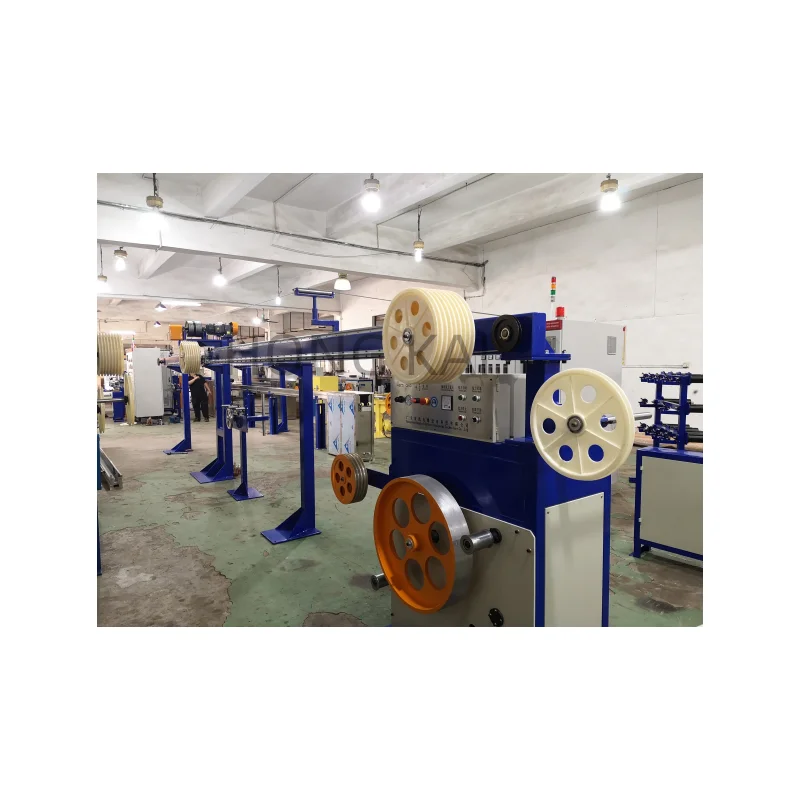

5.Our factory

6.Our main products

Indoor optical cable production line

Outdoor optical cable production line

7.Our service

A.Reply your enquiry in 24 working hours

B.Experenced machine and workart engineer answer your questions in professional

C.Customized design is available

D.Exclusive and unique solution can be provide to our customer by our well-trained and professional engineer

E.Our company policy:Good products,reasonable prices,sincere services,accurate delivery .

8.FAQ

A.What can we supply for our customer?

Our professional production technology staff can train your staff ,our R&D team can give you better design according

to your special requirment.100% inspection before shipement.

B.What's the payment terms ?

We accept T/T ,L/C

C.Hong long is the machine warranty period ?

the warranty is for one year (since the products have installed in the buyer's factory) based on technique condition,

during the warranty, the supplier shall take the change of parts free of charge due to quality elements.Unless otherwise

caused by other reasons, the buyer shall pay the cost of parts itself. All these two conditions, the buyer Shall be responsible for the roundtransportation expenses for equipment maintenance or replacement and accommodation expenses and other related expenses

for the staff sent by the seller, while the supplier assigns relevant technicians and provides machine parts.

D.What's the Terms of packing ?

simple packing with plastic film, no need to return. if need wood packing or other special packing,need another fee .

E.How many years our company set up?

From 2005 we start make electric wire and cable machine,then 2006 our factory began to invest in R&D of optical cable

machine.Now our products have been selling well to many customers at home and abroad.and win good repution and long-term cooperation relationships.

Welcome to our website and hope to you are interseted in our machines.Thank you!