HK-50 PLC + IPC CONTROL LOOSE TUBE PRODUCTION LINE

The HK-50 PLC + IPC Control Loose Tube Production Line by Hongkai is a state-of-the-art solution designed for the Outdoor Optical Cable Equipment industry. This advanced production line combines PLC+IPC control technology to deliver unparalleled precision, efficiency, and reliability in the manufacturing of loose tube cables. Ideal for loose tube production lines and optical cable production lines, the HK-50 is engineered to meet the highest industry standards, ensuring exceptional performance for outdoor optical cable production.

- Overview

- Related Products

-

PLC+IPC Control System: Provides seamless automation and real-time monitoring for enhanced production accuracy.

-

High-Speed Production: Optimized for efficient and continuous operation in optical cable production lines.

-

Durable Construction: Built with robust materials to withstand demanding industrial environments.

-

User-Friendly Interface: Simplifies operation and maintenance, reducing downtime.

-

Versatile Compatibility: Suitable for various applications, including loose tube production lines.

-

Energy Efficiency: Designed to minimize energy consumption while maximizing output.

-

Precision Engineering: Ensures consistent quality and performance for all cable types.

-

Telecommunication Networks: Ensuring high-quality cable production for reliable communication infrastructure.

-

Fiber Optic Manufacturing: Perfect for optical cable production lines requiring precision and consistency.

-

Industrial Cable Production: Supports the creation of durable cables for harsh outdoor environments.

-

Loose Tube Cable Systems: Ideal for loose tube production lines, providing superior performance and flexibility.

Key Features:

Applications:

The HK-50 PLC + IPC Control Loose Tube Production Line is widely used in the production of outdoor optical cables, making it an essential component for:

With its cutting-edge technology and versatile applications, the HK-50 PLC + IPC Control Loose Tube Production Line from Hongkai is the ultimate choice for businesses seeking to enhance their Outdoor Optical Cable Equipment production capabilities.

EQUIPMENT APPLICATION

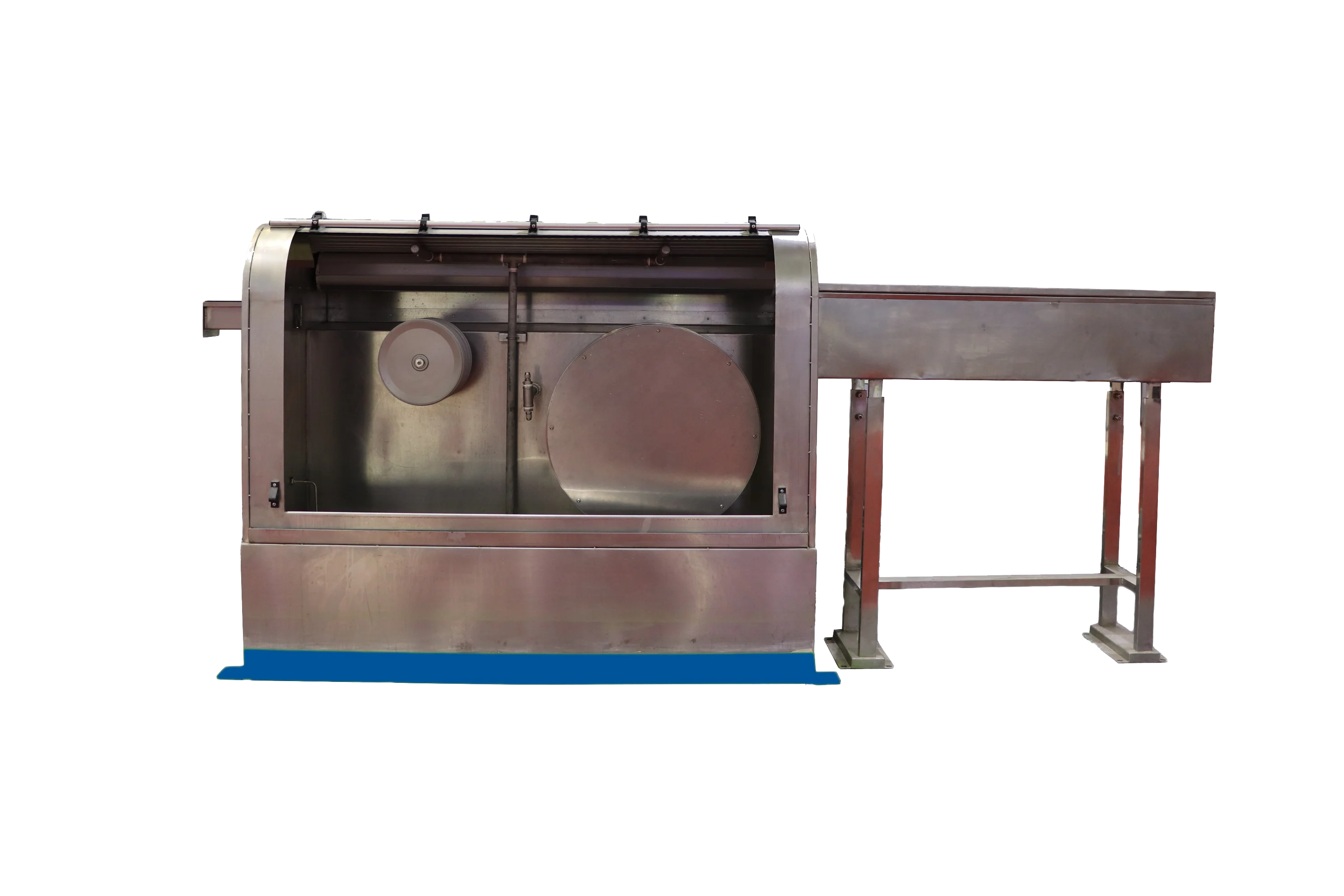

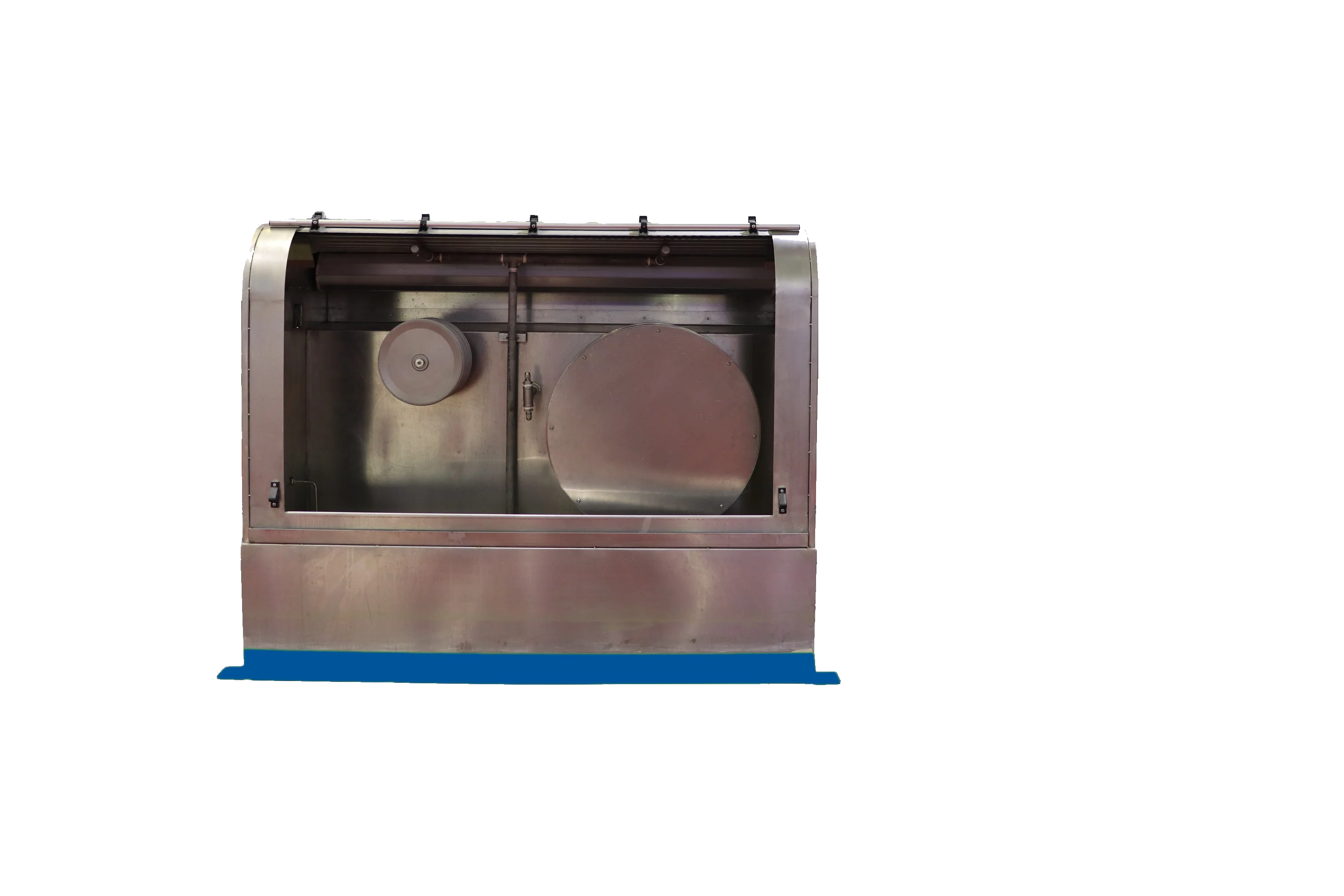

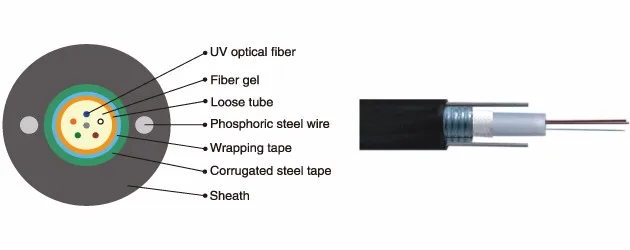

Mainly applied in the extrusion of 2~12 cores oil -filled fiber

High configuration, the machine use IPC+PLC control system, main electric parts are importing, screw adopt the modern latest technology, Gear tooth surface abrasion resistance.Low energy consumption of the equipment, a large quantity of extrusion, high production efficiency, high gloss surface, small temperature difference, low noise, good stability, strong continuity of working, convenient operation, long service life.

|

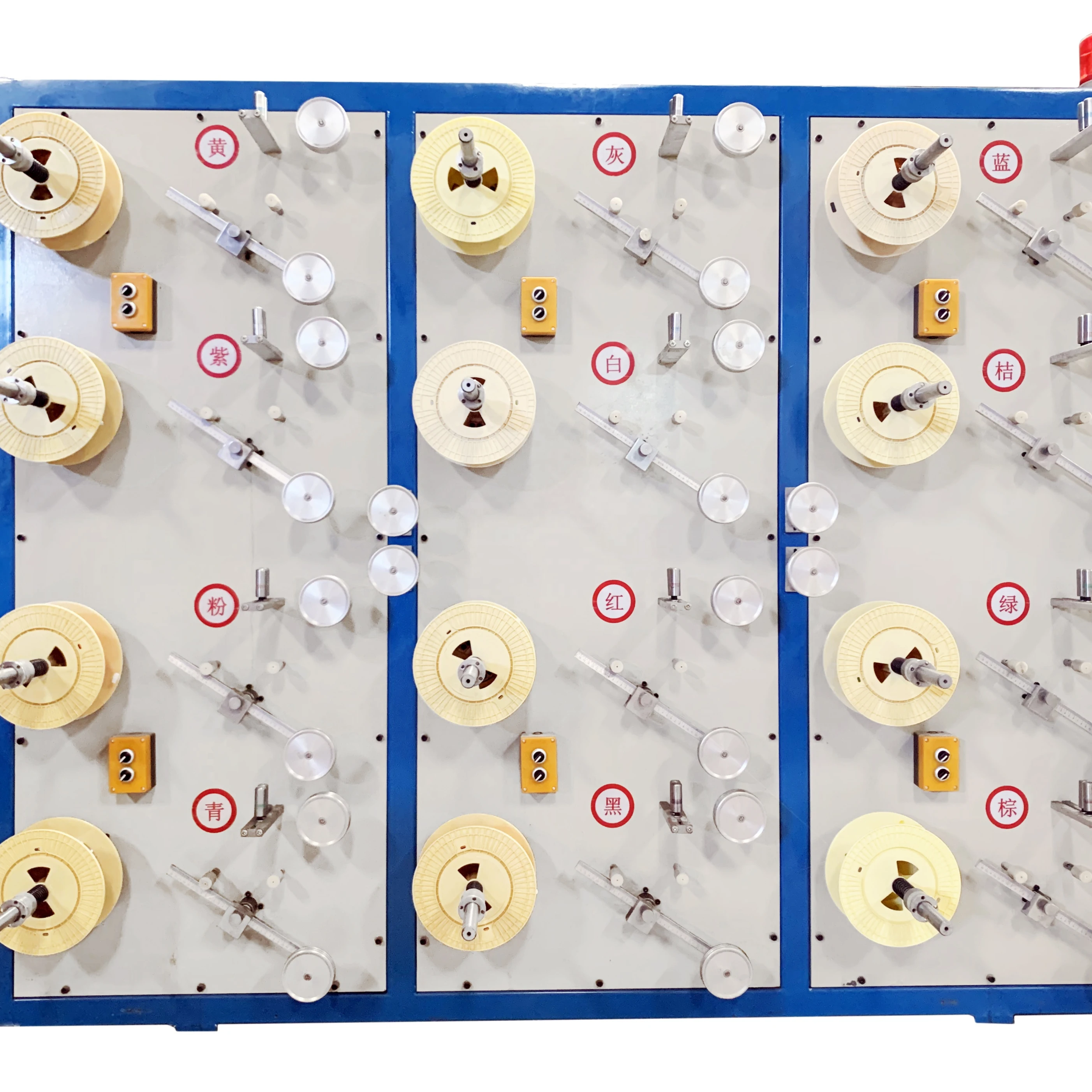

specification optical fiber pay off reels

|

φ236*φ160*108*φ25.4mm

φ236*φ160*225*φ25.4mm

|

Uniformity of excess length

|

0~3%±0.2%

|

|

Cores no of optical fiber

|

≤12 core

|

Specification optical fiber take up reels

|

PN630~PN800mm

|

|

Pay off tension

|

φ0.4~1.5N±0.05N

|

Fiber excess attenuation

|

≤0.02dB/km

|

|

Extruder type

|

SJ40/25D

|

Line length

|

32m

|

|

Loose tube diameter

|

φ1.6~4.0mm

|

Error of Measuring meter

|

<1%

|

|

Design speed

|

350m/min

|

center height of machine

|

1000mm from background

|

|

Actual speed

|

≤300m/min

|

Power

|

380v±10%50Hz Three phase five line 60KW

|

About Us

Guangdong Hongkai Optical Cable Equipment Technology Co.Ltd.is a professional company which

specializes in developing and manufacturing optical fiber cable equipments, electric wire and cable

equipments, telecommunications wire and cable equipments. We can also supply a whole set of

services including whole factory planning, equipments staff training, after-sales service, etc.

|

Indoor optical fiber production line

|

||||||

|

outdoor optical fiber production line

|

||||||

|

wire and cable equipment series

|

||||||

|

word exposition

|

||||||

|

If you want to learn more about us , please don't hesitate to contact me !!!

|

||||||